+8615158067512

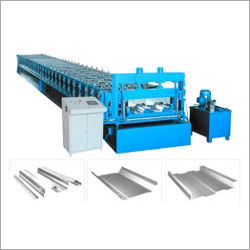

Metal Roll Forming Machine

Product Details:

- Type Roll Forming Machine

- Computerized No

- Automatic Grade Automatic

- Voltage 220-240 Volt (v)

- Warranty 1 Year

- Click to View more

Metal Roll Forming Machine Price And Quantity

- USD ($)

- 1 Set

Metal Roll Forming Machine Product Specifications

- 1 Year

- No

- Automatic

- 220-240 Volt (v)

- Roll Forming Machine

Metal Roll Forming Machine Trade Information

- 10 Set Per Month

- 40 Days

Product Description

The Metal Roll Forming Machine allows production of traditional tile panel. They can also be used to produce fastened tile panels. They have adjustable depth and an adjustable reveal that helps to give panels the appearance of clay tiles. These machines are capable of forming two different roof tiles with the same tooling. The Metal Roll Forming Machine are used to create perfect, scrape free finish. Further, the tiles produced are beautiful, elegant and noble in design. They can be used as the roof of garden, factory, hotel, exhibition center, villa, etc.

Detailed Product Description :

|

Material Of Cutter: |

Cr12 Mould Steel With Quench Treatment, HRC58-60 |

Material Of Forming Rollers: |

Cr12 Mould Steel Being Quenched Treatment |

|

Material Of Shaft: |

High Quality 45# Steel |

Main Power: |

11KW |

|

Hydraulic Power: |

5.5kw |

Production Speed: |

About 5m/min. |

|

Machine's Installation Size: |

35000X1800X2000mm (l x w x h) |

Punching: |

Automatic Punching Continuously |

|

Controller: |

Mitsubishi PLC |

Cutting Style: |

Automatic Hydraulic Cutting |

Technical data of shelving cold roll forming machine :

|

Suitable raw material |

Q235A galvanized steel sheet; thickness:2.0-2.5mm |

|

Forming speed |

about 7-10m/min. |

|

Production speed |

About 3-5 m/min. |

|

Material of forming rollers |

Cr12 mould steel being quenched treatment, |

|

Material of cutter,punching die |

Cr12 mould steel with quench treatment, HRC58-60 |

|

Material of shaft |

High quality 45# steel with heat treatment. Roller grinder milling. |

|

Main power |

11 KW |

|

Total motor power |

about 19 Kw(Depend on final design) |

|

Control system |

Mitsubishi PLC & converter |